India must tap its engineers to achieve ‘smart’ manufacturing says Global CEOs … writes Nishant Arora

As 3D printing appears set to transform the manufacturing sector globally, including in India, top global executives have emphasised that the country should invest in its talented pool of engineers to achieve “smart” manufacturing goals.

While the global 3D printing industry is pegged at somewhere between $4 billion and $5 billion, market intelligence solutions firm 6Wresearch predicts that India’s 3D printer prototyping and materials market will hit $79 million by 2021.

Manufacturing today is a $12 trillion market globally which 3D printing — or Additive Manufacturing (AM) — is set to disrupt, and India has a bigger role to play, the corporate honchos say.

“India produces the best engineers in the world. When it comes to manufacturing, the country should tap into its talent pool to help it move towards ‘smart’ manufacturing. Not just 3D printing, adopting automation and robotics will further boost India’s manufacturing dreams,” Gian Paolo Bassi, CEO at SOLIDWORKS, Dassault Systemes, told IANS.

He, however, lamented the lack of global talent when it comes to design for 3D printing.

“In order to succeed, we need to fast prepare a qualified workforce and research institutes, universities and colleges globally must nurture the talent towards New Age technologies,” added Bassi, who spearheads the development of future product and technology strategies designed for the desktop and the Cloud.

Bassi was speaking on the sidelines of the annual “SOLIDWORKS World 2018” conference here that saw the gathering of over 5,000 members of the SOLIDWORKS community.

SOLIDWORKS, offered by France-based Dassault Systemes — a leader in 3D design and engineering software — covers all aspects of product development process: Design, verification, sustainable design, communication and data management – all with a seamless, integrated workflow.

According to Stephen Nigro, President, 3D Printing Business, HP Inc., the prospects of 3D printing are very bright for India.

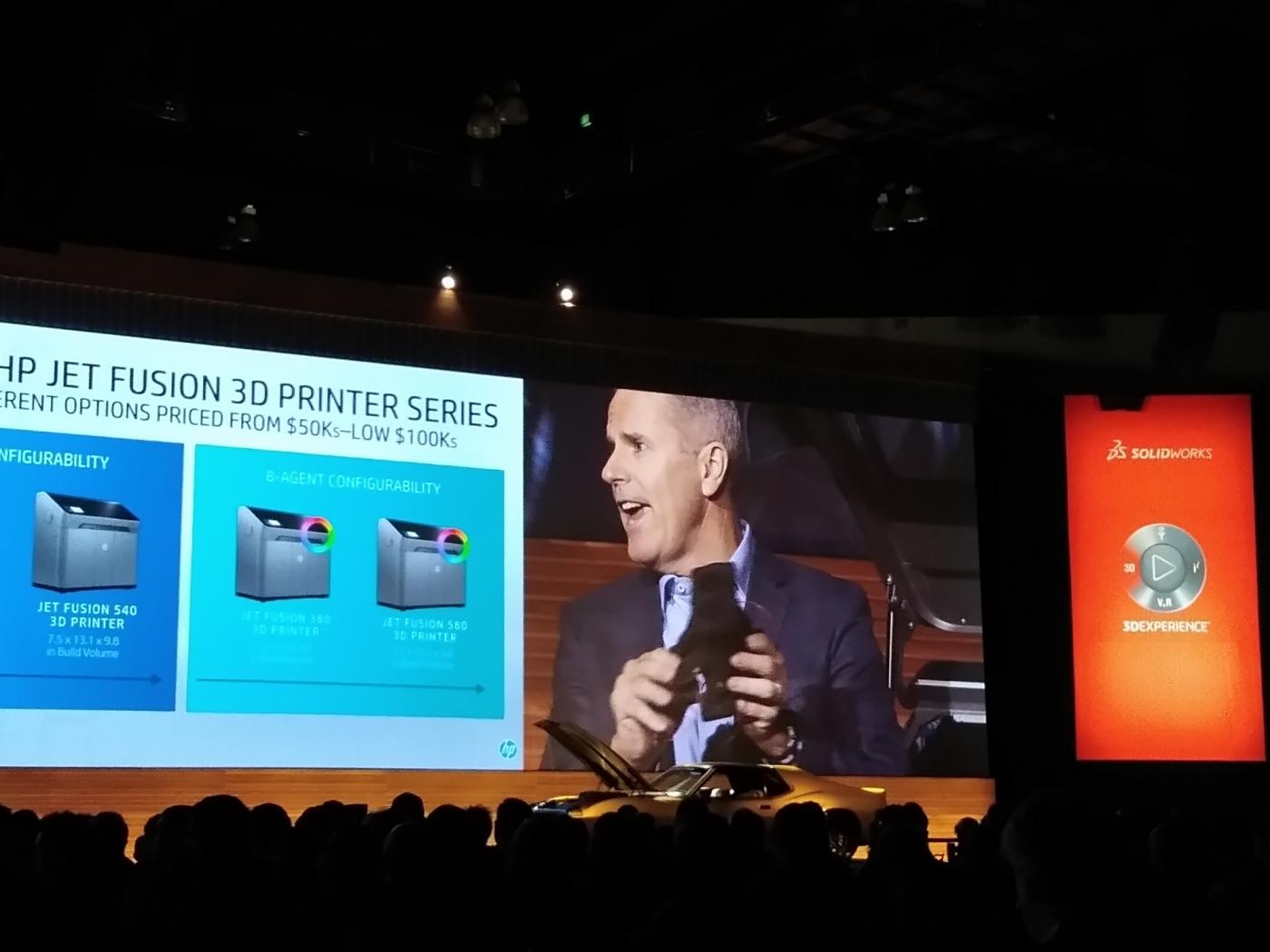

“Although relatively a small market at the moment, India offers a fantastic opportunity for 3D printing in the years to come. HP’s latest 3D printers are now available in the Indian market and we will ramp up our efforts to reach out to industry stakeholders,” Nigro told IANS.

HP and Dassault Systemes announced a unique collaboration where the two companies aim to optimise Dassault Systemes industry-leading “SOLIDWORKS 3D” design and engineering applications to take advantage of the unique capabilities of HP’s Multi Jet Fusion (MJF) 3D printing solutions.

While India’s manufacturing activities in product design, R&D and assembling has the potential to reach $1 trillion by 2025, a third of Dassault Systemes’ R&D capacity is supported by its facilities in India.

“We are doing a lot of research in design technology in India. What excites me is that there is lot of focus on design for 3D printing in the country. One has to start from design to succeed in the 3D printing business,” Bassi noted.

Dassault Systemes is bullish on India when it comes to training and nurturing young start-ups working in the 3D-printing space.

Indian mechanical engineering schools are among the highest adopters of SOLIDWORKS software — a solid modelling computer-aided design (CAD) and computer-aided engineering (CAE) computer programme.

Dassault Systemes is also helping the thriving start-up community via incubators in the country. The company is also planning to forge partnerships with academic universities to create more visibility for better outreach.

Last month, it partnered with the Andhra Pradesh State Skill Development Corp (APSSDC) to set up a “3DEXPERIENCE” centre to prepare industry-ready students.

The centre will enhance the employability skills of the engineering and polytechnic (diploma) students on its “3DEXPERIENCE” platform for the fields of aerospace and defence, automotive and ship-building.

The aerospace and defence industry in India is one of the fastest-growing in the world with a significant push to indigenous manufacturing.

The “3DEXPERIENCE” platform helps businesses design and test in a simulated production environment so that they can efficiently plan, produce and manage resources.